Giving new life to tyres and conveyor belts

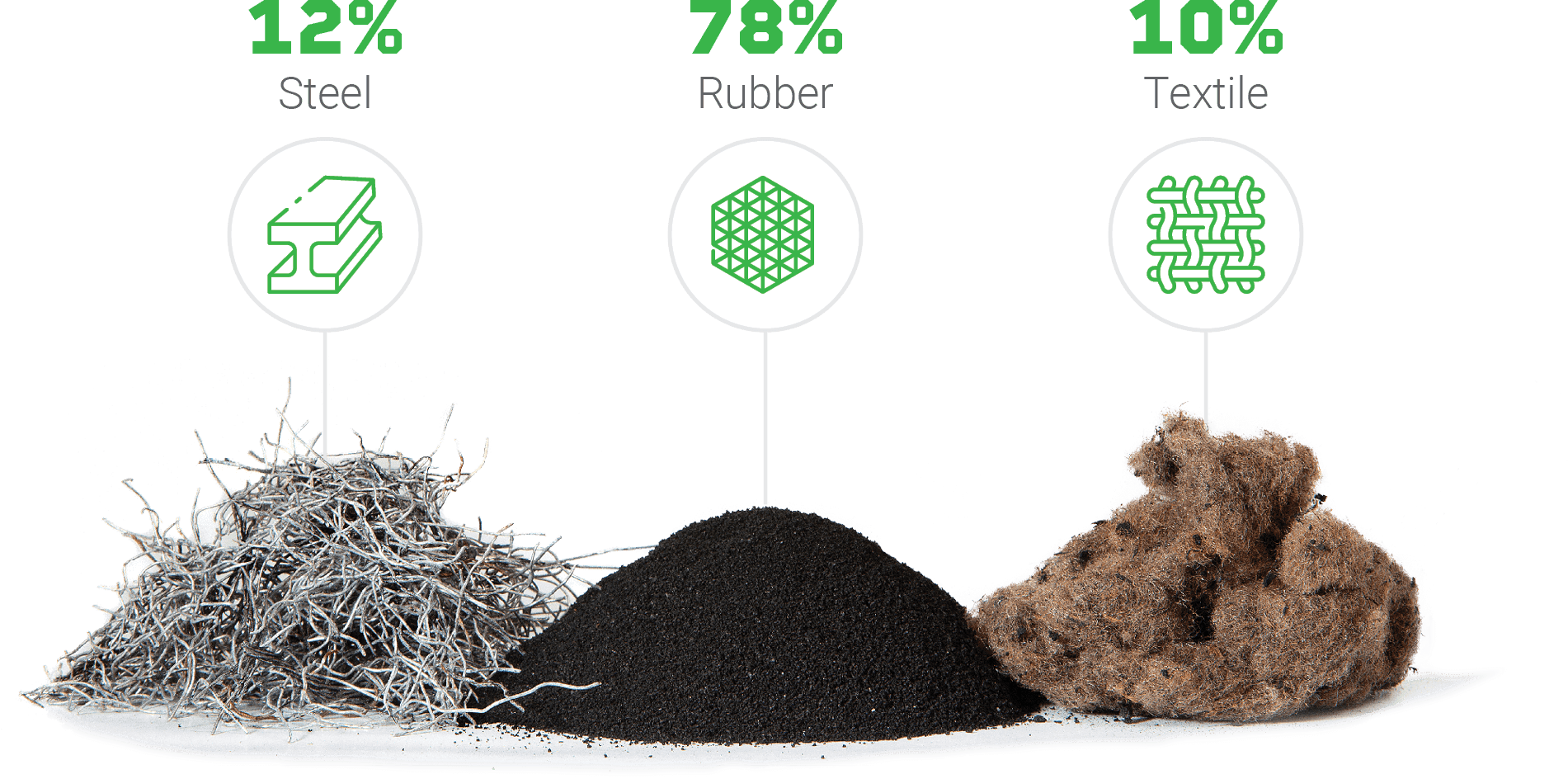

The average commercial tyre can be split into 3 core components: Rubber, steel & textiles.

Quality control

RubberGem is very particular about what we recycle, because it has a direct impact on the quality, consistency and durability of our products, which are made to exacting standards. Our products are tested in both internal and external laboratories on a daily basis to ensure they meet our high standards, and exceed customer expectations.

Capacity

Our facility is capable of processing and holding stock for an enormous amount of unprocessed and processed materials, and our transport and logistics network is constantly growing.